Industrial Engineering & Services

Consultancy service, Marketing, Construction and Erection of Industrial Project

Consultancy service, Marketing, Construction and Erection of Industrial Project

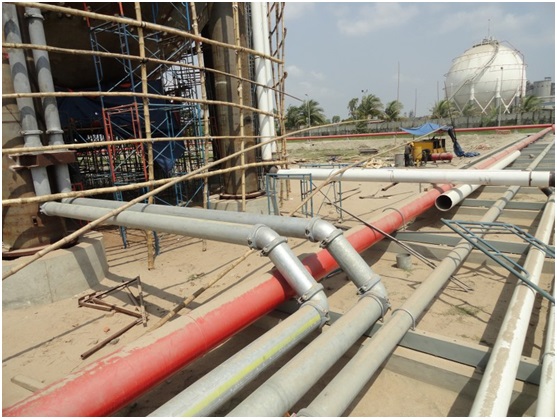

| Project Name : | Omera LPG Import Terminal and Bottling Plant (Year 2013-2014). |

| Supplier Name : | PARLYM International. |

| Client Name : | Omera Petroleum Limited. |

| Location of the Project : | Mongla, Khulna, Bangladesh. |

| Status of the Project : | COMPLETED |

| Scope of the Work : | Execution of Equipment Erection and Installation of OMERA LPG IMPORT TERMINAL AND BOTTLINGPLANTPROJECT. 1. GENERALITY Erection of a new LPG storage and distribution facility including LPG storage, LPG cylinder filling centre and LPG truck loading bays in Mongla, Khulna, Bangladesh. • Two (02 Nos.) Spherical LPG storage tanks. • Two (02 Nos.) LPG tank truck loading bays. • LPG cylinder filling centre. • LPG pumping facilities. • LPG ship unloading facilities • LPG piping systems. • A fire water pumping and distribution system. • Compressed Air production & distribution. • Electrical network. • Various utility and support facilities. A. SPHERICAL TANK STORAGE The LPG storage will be composed of Two (02 Nos.)spherical tanks each containing a geometric volume of 4189 m3. The erection works of spherical storages are: • Erection, welding, 100% radio and access. • Fire proofing oflegs. • Mounting of fire fighting network on sphere. • Under pressure testing. • Emptying sphere. • Sand blasting and Painting. MECHANICAL 1. BOTTLING HALL Erection of the material is described as bellow: 5.5 / 12.5kg filling line will be equipped with the following: - A set of chain/roller conveyors - An automatic washing machine - A tabulation post - A tangential pneumatic admission - A carousel frame 18 posts equipped with 9 electronic filling scales - An electronic check scale - A resetting check scale - An electronic infrared leak detector - An automatic thermo sleeve shrinking machine - 13 footbridges for chain conveyors - A computer assisted production management system 35kg filling line will be equipped with the following: - A set of roller conveyors - Two electronic stationary filling scales - An electronic stationary check scale - An electronic manual leak detector Maintenance centre will be equipped with the following: - Emptying stand 8 posts (5.5 / 12.5kg cylinder) - Tilting emptying post (35kg cylinder) - Cylinder evacuation unit - Two manual valve unscrewing/screwing units - A cylinder foot ring and shroud straightening unit C. LPG PUMP SHELTER Installation of Six (06)Nos LPG Pumps and Two (02 Nos)LPG Compressors UTILITIES SHELTER • Installation of two (02) diesel pumps, electric boards, diesel tanks and an electric jockey pump. • Installation of the air compressors, dryers and air tanks. • Installation of a container 20’ for water treatment. • Installation of theTwo (02 Nos.) Fire fighting water tanks (3000m3 each) andFive (05 Nos.) Water tank (10m3 each). • Installation of the weighing bridge. Two (02Nos.) Fire Fighting Tank (Each capacity 3000 m3) E.PIPING 1. LPG NETWORK • LPG storage • LPG pumps shelter • LPG truck loading • LPG bottling hall • LPG jetty • LPG interconnecting network FIRE FIGHTING NETWORK (Wet & dry networks) • FF utilities shelter • FF tank piping • FF pump shelter • FF truck loading • FF storage area • FF bottling hall • FF jetty • FF deluge collector WATER NETWORK • WA utilities shelter • WA bottling hall • WA utilities shelter • WA to buildings (potable water) WA interconnecting 5.DIESEL NETWORK • Diesel utilities shelter • Diesel interconnecting network |

Copyright © 2017 - All Rights Reserved - Industrial Engineering and Services

Designed by ixplore Bangladesh